Micron Precision can offer the complete package

Welcome to Micron Precision

About Us

Our Products

Welcome to the Future

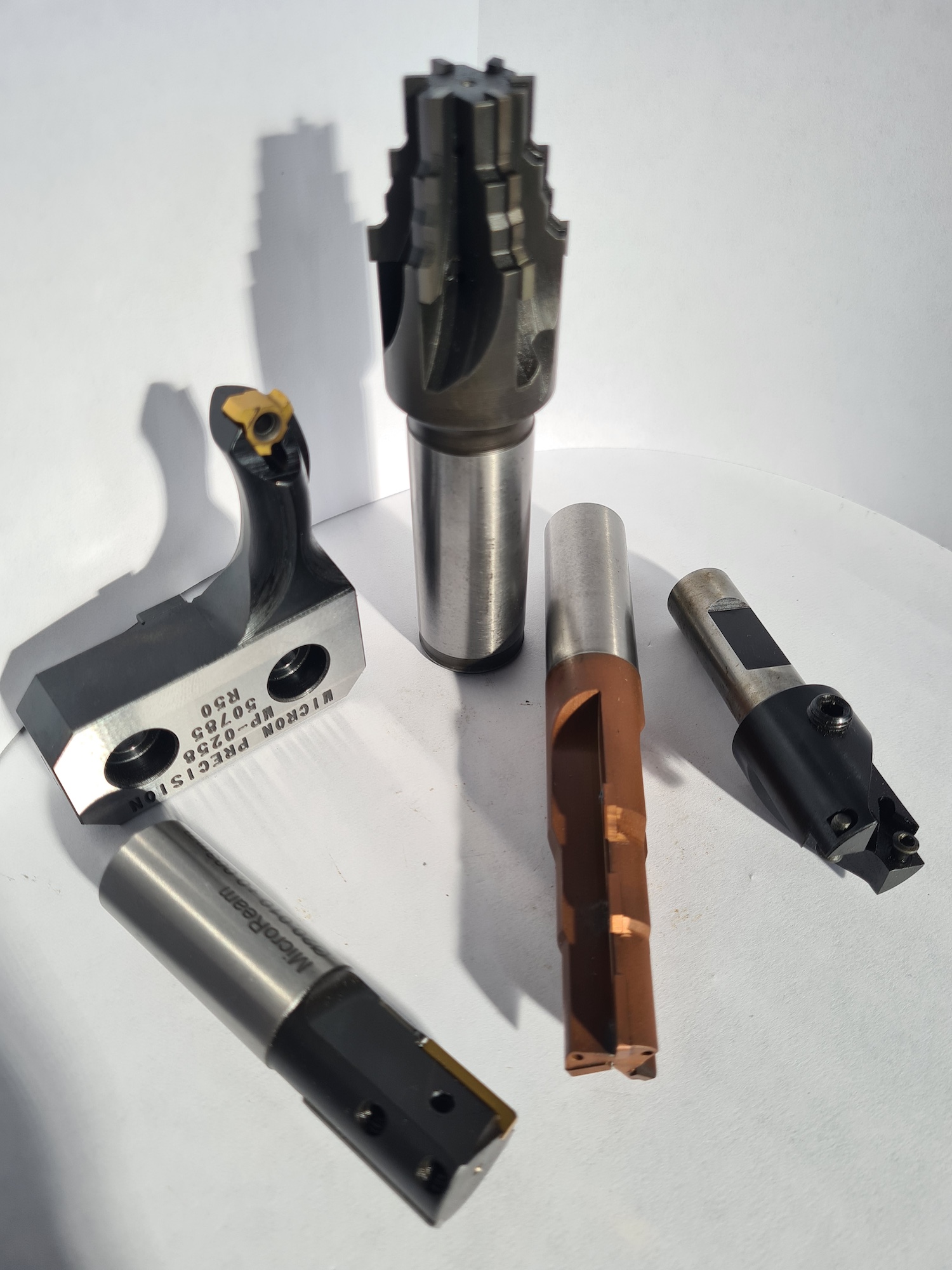

Micron Precision design and manufacture in house a wide range of special cutting tools including Micro-Ream single blade reamer & fine boring tools, PCD reamers and form tools, brazed carbide form tools, multi-flute reamers and special purpose indexable insert tooling.

Continuous investment in the latest CAD / CAM and CNC technology ensures Micron Precision is always at the forefront of supplying quality special tooling to it’s wide and varied customer base.

Micro-Ream

Single blade reamers and fine boring tools designed and manufactured by Micron Precision. The reamer has two or more carbide or cermet guide pads strategically positioned to absorb the cutting forces applied, these are accurately ground and lapped to guide the tool through the bore.

The cutting blade is adjusted via the two adjusting screws, pushing onto an adjusting wedge which in turn pushes the blade out to it’s correct cutting diameter.

The reamer has a standard range of blades to accommodate the diverse range of materials used in today’s manufacturing industry.

- Single blade reamers

- Fine boring tools

- Multi diameter fine boring tools

- Fine boring tools with spot-facing / chamfering facilities

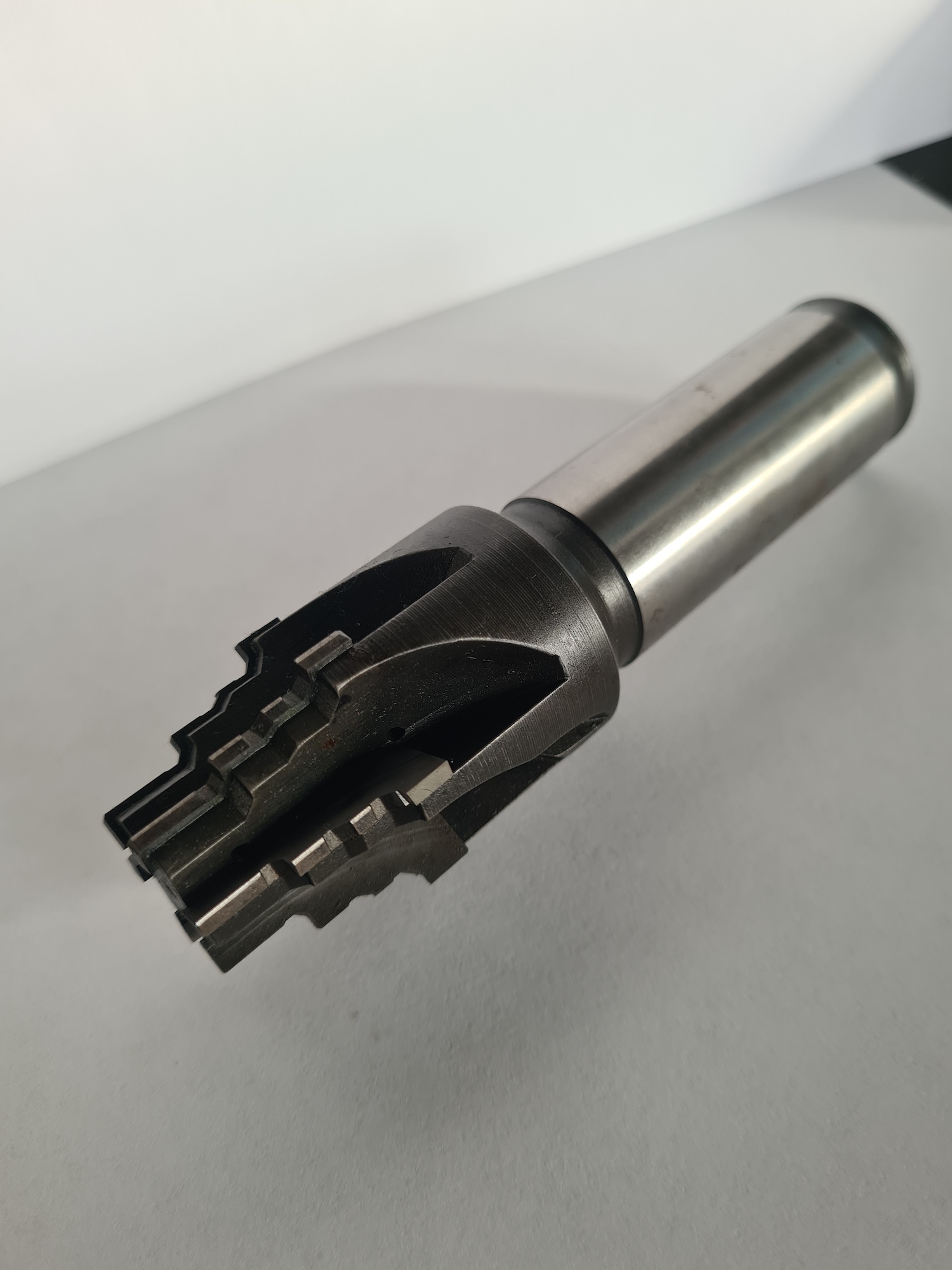

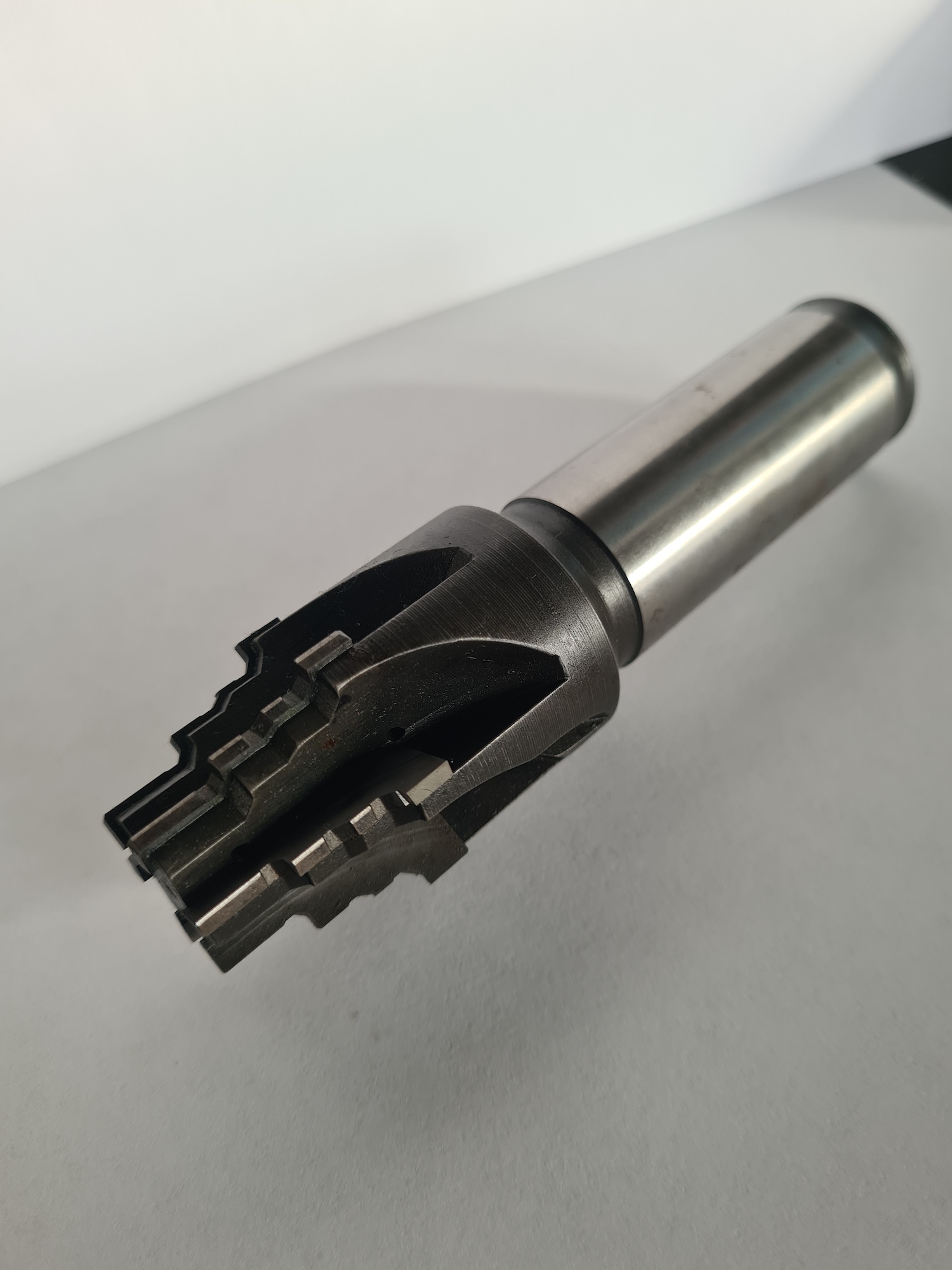

Single Blade Reamer Repair

All tool repairs are guaranteed to perform as they did when they were supplied as new.

From a straight forward worn pad replacement to the more serious body damage, where it is still cost effective to have the tool body built up and re-cut to restore the tool to it’s original condition.

SEE BELOW FOR BEFORE IMAGE

PCD Tooling

These materials are used in our special tooling applications which come in a wide variety of designs and supplied on almost all of today’s modular location systems.

PCD is used in our special tooling and are mainly used for finishing applications. The tools come in a wide variety of designs and are supplied on almost all of today’s modular location systems.

- Reamers

- Spot facing tools

- Fine boring tools

- Multi diameter step and form tools

- Milling applications

Indexable Tooling

This type of tooling is mainly used for roughing out or semi-finishing components, where drawing tolerances allow, this type of tool may be used for finishing.

- Special Application Slotting Tools

- Combination Boring Counterboring & Chamfering Tools

- Combination Drilling, Spot-facing & Chamfering Tools

- Combination Boring Tools with micro adjustment

Multi Flute Reamers

- Multi-flute Reamers

- Multi-flute Fine Boring Tools

- PCD Multi-flute Reamers

- Combination Cutting Rings

Formed Inserts

Micron Precision design complex forms that are machined in all cutting materials used throughout the manufacturing industry, this allows one simple form or multi features to be machined at any one time.

- HSS blades

- Formed Indexable inserts

- Carbide, PCD / CBN blades

Contact Us

Our Address

Unit 4

29 Wigston Street

Countesthorpe

Leicestershire

LE8 5RP

Company Number

Directions

Website Terms & Conditions

If you continue to browse and use this website you are agreeing to comply with and be bound by the following terms and conditions of use, which together with our privacy policy govern Micron Precision’s relationship with you in relation to this website.

The term ‘Micron Precision’ or ‘us’ or ‘we’ refers to the owner of the website whose registered office is Sparkenhoe Business Centre, Southfield Road, Hinckley, LE10 1UB. Our company registration number is 04824775. The term ‘you’ refers to the user or viewer of our website.

The use of this website is subject to the following terms of use:

- The content of the pages of this website is for your general information and use only. It is subject to change without notice.

- Neither we nor any third parties provide any warranty or guarantee as to the accuracy, timeliness, performance, completeness or suitability of the information and materials found or offered on this website for any particular purpose.

- You acknowledge that such information and materials may contain inaccuracies or errors and we expressly exclude liability for any such inaccuracies or errors to the fullest extent permitted by law.

- Your use of any information or materials on this website is entirely at your own risk, for which we shall not be liable. It shall be your own responsibility to ensure that any products, services or information available through this website meet your specific requirements.

- This website contains material which is owned by or licensed to us. This material includes, but is not limited to, the design, layout, look, appearance and graphics.

- Reproduction is prohibited other than in accordance with the copyright notice, which forms part of these terms and conditions.

- All trade marks reproduced in this website which are not the property of, or licensed to, the operator are acknowledged on the website.

- Unauthorised use of this website may give rise to a claim for damages and/or be a criminal offence.

- From time to time this website may also include links to other websites.

- These links are provided for your convenience to provide further information. They do not signify that we endorse the website(s). We have no responsibility for the content of the linked website(s).

- You may not create a link to this website from another website or document without Micron Precision’s prior written consent.

- Your use of this website and any dispute arising out of such use of the website is subject to the laws of England, Scotland and Wales.